压实密度(compacted density)

一. 定义:Definition

压实密度的计算公式:压实密度=面密度/材料的厚度

在锂离子电池设计过程中,压实密度=面密度/(极片碾压后的厚度—集流体厚度) ,单位:g/cm3

Compaction density calculation formula: the compaction density =surface density/ thickness of material

In the process of lithium ion battery design, compaction density = surface density / (The thickness of the pole plate after crushing - current collector thickness), unit: g/cm3

压实密度分为:负极压实密度Anode density(或称为阳极压实密度)和正极压实密度Cathode density(或称为阴极压实密度)。

Compaction density is divided into: the cathode compaction density (or is called the Anode compaction density) and the Anode compaction density (or called the Cathode compaction density)

二. 原理: Principle:

锂离子动力电池在制作过程中,压实密度对电池性能有较大的影响。通过实验证明,压实密度与片比容量,效率,内阻,以及电池循环性能有密切的关系。

In the process of making lithium ion power battery, The compacting density has a large effect on battery performance.The test results show that the compaction density is closely related to specific capacity, efficiency, internal resistance and the performance of the battery cycle.

找出压实密度对电池设计很重要。一般来说,压实密度越大,电池的容量就能做的越高,所以压实密度也被看做材料能量密度的参考指标之一。

It is important to find the optimal compaction density for battery design.Generally speaking, the higher the density, the higher the capacity of the battery, so the compacted density is also seen as a reference indicator of the energy density of the material.

压实密度不光和颗粒的大小、密度有关系,还和粒子的级配有关系,压实密度大的一般都有很好的粒子正态分布。可以认为,工艺条件一定的条件下,压实密度越大,电池的容量越高。

The compaction density is not only related to the size and density of the particle, but also related to the level of the particle, Normally, High compaction density has a good particle normal distribution.It can be said that under certain conditions ,The higher density of the battery, the higher capacity of the battery.

合适的正极压实密度可以增大电池的放电容量,减小内阻,减小极化损失,延长电池的循环寿命,提高锂离子电池的利用率。在压实密度过大或过小时,不利于锂离子的嵌入嵌出。

The proper positive electrode compaction density can increase the discharge capacity of the battery, reduce the internal resistance, reduce the loss of polarization, extend the cycle life of battery, Improve the utilization rate of lithium ion batteries. If the The compacted density is too large or too small , It is bad for the embedding of lithium ions.

三.适用范围:Scope of application

在外力的压缩过程中,随着粉末的移动和变形,较大的空隙被填充,颗粒间接触面积增大,使原子间产生吸引力且颗粒间的机械楔合作用增强,从而形成具有一定密度和强度的压坯.

In the process of the compression of external force, As the movement and deformation of powder, larger gap is filled, The contact area between particles increases, The interatomic appeal and mechanical wedge cooperation between particles will be enhanced, Thus forming a certain density and intensity of compact.

满足标准:GBT 24533-2009 锂离子电池石墨类负极材料,附录L:粉末压实密度的测试方法,

Meet standard: GBT 24533-2009 lithium ion battery graphite type anode materials, appendix L: Test method of powder compaction density,

也可以用于具有类似特性之粉末和颗粒压实密度之测定;国际上粉末和颗粒测试方法相通。

It can also be used for the determination of powder and particle’s compaction density which have similar properties; The test methods of powder and particle are similar internationally.

四.功能描述:Function description:

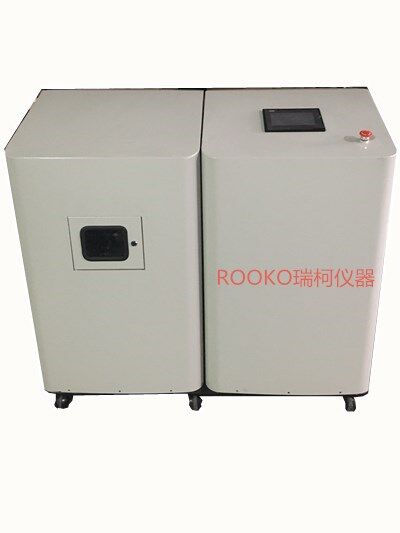

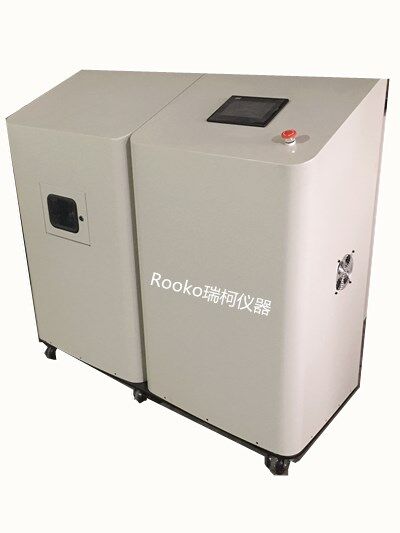

采用液压恒压加压测量系统,7寸触摸屏和PC软件控制,高精度荷重单元控制系统能精确采集应力变化数据,可以任意设置压力、时间数据,位移由位移传感器直读,温湿度数据通过传感器获得,多位数的AD芯片来保障数据的分析,全自动模式,手动操作模式及多段设置操作模式并存;配置PC软件可以获得应力与粉体密度关系曲线;时间与粉体屈服强度关系;过程数据的分析和曲线图谱,为生产企业和科研院所研发新品和改善工艺建立数据模型.提供中英文两种语言版本。

Adopts hydraulic constant pressureforcing pressure measurement system, 7 inch touch screen and PC software control, High precision load cell stress change control system can precisely collect the stress change data, Date such as pressure, time Can be arbitrarily set, Displacement direct reading by displacement sensor, the temperature and humidity data obtained from the sensor, Multidigit AD chip to ensure data analysis, Automatic mode, Manual mode and Multistage set operating modes coexist; Configuring PC software to obtain the stress and powder density curve;The relationship between the time and the yield strength of the powder;Analysis of process data and curve spectrum , Set up data model for production enterprises and scientific research institutes develop new products and improve the process. Provide both Chinese and English languages.

|

测试项目/test project |

技术 参数/ Technical parameter |

分辨率/Accuracy |

|

1.主压力/ Main pressure |

5吨;10吨;20吨;(选购)/ 1 tons; 5 tons; 10 tons; 15 tons; 20 tons(choose to buy) |

传感器:1级/ Sensor: class 1

|

|

2.位移测量/ displacement |

高精度位移传感器系统, High precision dial gauge |

0.001mm |

|

3.位移行程/ Displacement stroke |

0-60mm(可根据客户要求定做)/( Can be customized according to customer requirements) |

0.1mm |

|

4. 控制系统/ Control system |

液压恒压控制系统/ Hydraulic constant pressure control system |

|

|

5.显示方式/display |

7寸触摸屏/7 inch touch screen |

|

|

6. 模具/ mould |

内径:12.8mm;高:25mm(可定制)/ Inner diameter: 30mm,height:25mm(customizable) |

0.1mm |

|

7.脱模方式/ Demoulding method |

自动/ automatic |

|

|

8.安全装置/ Safety device |

自动诊断、过载保护和急停控制/ Automatic diagnosis, overload protection and emergency stop control |

|

|

9.温湿度范围/ Temperature humidity range |

常温-50度;湿度:20%-98%/ Room temperature -50 degrees, humidity:20%-98% |

|

|

10.时间设置/ time setting |

0-99.9S |

0.1S |

|

11.设备管理功能/ Device management function |

密码设置及数据管理存储/ Password settings and data management storage |

|

|

12.密度值/ Density value |

99.99999g/cm3 不同样品特性不同密度有所差异/ Different samples characteristics have different density. |

3%以内/ Less than 3% |

|

13.高精度测试天平(选购)/ High precision test balance(choose to buy) |

0.00001g,量程:120g/ Accurate to 0.00001g, range: 120g |

0.01% |

|

14.位移速度/ Displacement speed |

约15mm/min |

0.1mm/min |

|

12.使用环境要求/ Environmental requirements |

仪器使用环境要求:工作温度:-10℃-40℃,湿度:≤65%RH Environmental requirements for instruments:working temperature:-10℃-40℃,humidity:≤65%RH

|

|

|

13.电源/ Power Supply |

220V 50HZ或者380v/220V 50HZ or 380v

|

|

|

14. 整机不确定性误差/ Machine uncertainty error |

整机不确定性误差3%/ Machine uncertainty error 3% |

|

|

1. 选购项目 Choose and buy items |

电脑,打印机,其他规格模具 Computer, printer, other specifications mold |

|